The emission of tire and road wear particles (TRWP) is linked to car driving, especially under stress driving conditions. These particles pose risks to various ecosystems and environmental organisms, and their release and distribution patterns exhibit significant variability depending on driving behaviours, tire types, and road conditions.

Utility items are subject to constant wear and tear, either due to environmental influences such as light, water or heat, or due to their function. In the case of car tires, wear occurs during the driving and braking process and mainly microparticles are released. In addition to wear from the tire materials, also road wear particles are formed during driving. Further, the tire material contains a number of substances that are added to the rubber in order to obtain specific properties, for example nanomaterials like carbon black.

Hence, there is concern about potential health effects of such wear particles and their constituents for humans and the environment.

What are tire and road wear particles (TRWP)?

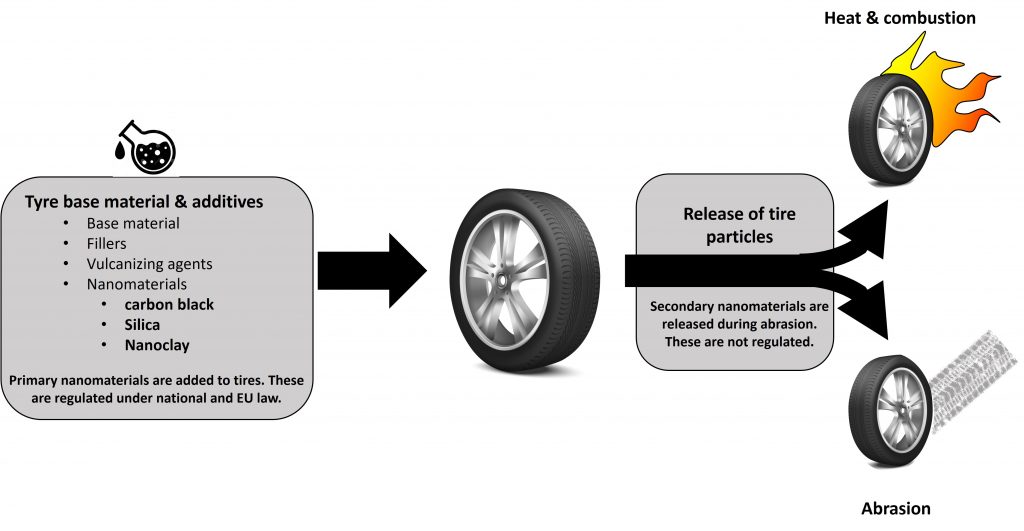

Car tires consist mainly of rubber including a wide range of chemicals as well as nanomaterials that influence the stability and resilience of tires. Tire wear particles (TWP) are defined as small debris that is generated during normal driving conditions due to the friction between the tire and the road, which is necessary for sufficient grip and safety (CSR Europe). Because rubber is a polymeric substance, TWP are classified as microplastics due to their size and composition. TWP combine with road wear to form Tire and Road Wear Particles (TRWP), which may also include particles from brake wear. Starting materials used in the formulation of tire tread rubber includes those that are chemically bound to the rubber matrix (e.g., carbon black) and those that are dispersed freely within the rubber matrix (e.g., plasticizers and anti-aging compounds). The fragmentation and degradation of plastics cannot be simply extrapolated to tire rubber particles. Tire rubber is a vulcanized polymer structure designed to withstand harsh conditions and ensure safe and durable driving. UV stabilizers, antioxidants, and anti-degradation compounds are added to prevent the degradation of tire rubber. Limited information is available regarding the degradation of tire rubber by environmental conditions. Only a small share of the tire tread rubber are manufactured or natural occurring nanomaterials ENMs such as carbon black, silica or nanoclay. The exact composition is only known to the manufacturers and is kept confidential due to patent rights. In any case, the nanomaterials are not released as pristine particles, but undergo aging as well combine with the other components of the tire. Due to wear effects during braking or fast driving, a mixture of micro- and nanosized TWP is released.

How are TRWP formed?

TRWP are generated during stressful driving conditions. This includes, for example, strong acceleration or braking. The high mechanical load causes abrasion of particles from tires and brakes. These are initially released into the air or adhere to surfaces (e.g., brake strips on roads).

Release of TWP is expressed as mass released per vehicle per kilometer driven (mg/v*km) or as mass released per year (g/a). Additionally, particle number-based metrics are increasingly being used. It is important to note that TRWP release varies significantly between normal and stressed driving conditions, such as cornering, rapid acceleration, and full-stop braking. Speed plays an important role here.

Under normal driving conditions, measurements show an average release of 64 mg/v*km (mg per vehicle per km). Slight braking at 90 km/h can release more than twice the amount of tyre and road abrasion particles than hard braking at 50 km/h. In terms of particle numbers, steady straight driving results in an estimated upper limit release around 1011 particles per kilometer. On an individual basis, the estimated release of TWP ranges from 0.23 to 4.7 kg/year per person, with a global average of 0.81 kg/year. It is estimated that 10-30% of the tread rubber is lost over the lifespan of a tire, contributing up to 30-50% of the total emitted non-exhaust particulate mass. In the EU alone, this amounts to approximately 1,120,000 tons/year of micro-sized TWP. Tyre wear differs greatly between different tyre brands. Regarding the fate of TRWP, a substantial portion, approximately 67%, ends up in the soil. Around 12% remain in the air, while 6% directly enter surface water, with an additional 12% indirectly reaching surface water through the sewage system. Airborne nanoparticles have the potential to be transported over long distances and may deposit in remote areas such as the high Alps, sandy regions, and even polar areas. In fact, deposits of TRWP have been associated with Greenland firn ice.

Human health and environmental risks

The risk of TRWP to humans and the environment can only be roughly estimated at the present time. This is mainly due to the lack of data on TRWP exposure on the one hand and a lack of hazard data on the other. In addition, there are several analytical challenges in measuring the release as well as the fate of TRWP due to the very heterogeneous composition of the released particles and the challenging isolation and separation of TRWP from the huge background of other particles present in the environment. However, there are several indications that released particles from tires may be a threat for human health and the environment [1,2].

1 human health

For human health, inhalation of TRWP possesses the biggest risk. TWP which are released in the air contribute to fine and ultrafine dust and can therefore be inhaled by humans. As the highest TRWP emission correlates with densely populated areas, the exposure is increased within big cities. Nevertheless, there is also a health risk in the rubber manufacturing industry as workers are exposed to emissions that are identified as being carcinogenic.

2 environmental effects

The use of rubber tires contributes significantly to the presence of microplastics in terrestrial, aquatic, and airborne environments. In fact, tire wear is a major contributor, estimated to account for over 25% of the total microplastics mass in the terrestrial environment. TRWP are especially contributing to microplastic load in the oceans as they are transported into the oceans via rivers. The particles as well as the associated chemicals might be hazardous for aquatic organisms. The leaching of additives from TWP might be facilitated by environmental conditions like rain and pH, and accordingly poses additional hazard for aquatic ecosystems. For example, observed effects for aquatic organisms range from behavioral changes to reduced growth and reproduction to higher mortality. Taken all these aspects together, airborne release of TRWP has the potential to impact individuals, ecosystems, and the environment both locally (deposition on and near roads) and in more distant terrestrial and aquatic areas following transport.

Challenges in context with tire and road wear particles

In general, the concerns associated with tire wear particles arise from their heterogeneous mixture with road wear particles (TRWP), which exhibit varying shapes, sizes, surface areas, and chemical compositions, most of which have an undetermined hazard potential. Regarding the manufactured nanomaterials contained in the tread rubber, it is unclear if and how they are released. In any case, release does not occur in their original form, but rather as embedded components within abraded micro and nano rubber particles that in addition have undergone chemical transformations.

Mitigation measures: What can be done to reduce tire wear?

To minimize the release of particles while driving, a change in driving behavior is an effective measure. By avoidance of stress driving and through measures like speed limits and the promotion of lighter vehicles, the release of TRWP can be reduced. Lower speeds and anticipatory driving leads to less wear on the car tires. Furthermore, the update of the European tire label (2021) is showing more information about energy efficiency (rolling resistance), wet grip, giving the consumer the chance to choose between different tires. In addition, ongoing research aims to explore new materials (which includes also new nanomaterials as additives) that can improve tire properties and reduce environmental impact. However, risks vs. benefits are often not easy to break down. For example, a newly developed car tire that has more grip may lead to increased abrasion and wear of the tire, but it helps to improve driving safety. Ultimately, this can prevent heavy abrasion due to reduced heavy braking.

Last but not least, the formation of tire wear is studied and aims to improve or optimize the composition of the tires, the infrastructure or their maintenance.

Literature

- S. Wagner, P. Klöckner, T. Reemtsma, Aging of tire and road wear particles in terrestrial and freshwater environments – A review on processes, testing, analysis and impact, Chemosphere, Volume 288, Part 2, 2022, 132467

- K. Müller, D. Hübner, S. Huppertsberg, T. P. Knepper, D. Zahn: Probing the chemical complexity of tires: Identification of potential tire-borne water contaminants with high-resolution mass spectrometry, Science of the Total Environment, 2022, 802, 149799

Further Information

- THE EUROPEAN PARLIAMENT AND THE COUNCIL OF THE EUROPEAN UNION. REGULATION (EU) 2020/740 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 25 May 2020 on the labelling of tyres with respect to fuel efficiency and other parameters (https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32020R0740#document1)

- Airborne release of tyre wear particles NanoRigo (2022), Technical Report (Link to PDF)

- Tyre wear nanoparticles as test for a nano risk governance framework, Frontiers in Environmental Science, December 2022, 10