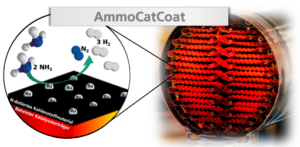

AMMOnia reforming with electrically heated CATalyst supports COATed with biomass-based carbon materials

To drive the decarbonization of economies worldwide and achieve the Paris climate goals, it is necessary to produce sustainably generated hydrogen (H2) in large quantities and to store it efficiently and cost-effectively. For Germany, as an energy-importing nation, the transition from fossil to green energy sources is of central importance. Ammonia (NH3), as a carbon-free energy carrier that can be easily liquefied, is an efficient and cost-effective transport option in many scenarios, particularly because the shipping and port infrastructure for industrial quantities is already in place. A meaningful expansion of the application possibilities for imported green NH3 is its reconversion into H2 through catalytic reforming. The produced hydrogen can additionally be supplied to the industrial and transport sectors.

Furthermore, methods for reducing atmospheric carbon dioxide levels are gaining importance. In this context, biochar offers itself as a raw material for material use and long-term carbon binding. Biochar can be used as an additive in concrete or road surfaces, as an adsorbent material for filtration systems, and as a catalyst or catalyst support for the chemical industry. Additionally, reactors with efficient electric heating are used to promote the electrification of the chemical industry.

The goal of the research project AmmoCatCoat is to investigate novel, biomass-based carbons as ruthenium (Ru) carrier materials for industrial hydrogen production from ammonia, as well as the use of electrically heated catalyst supports.