Properties and Applications

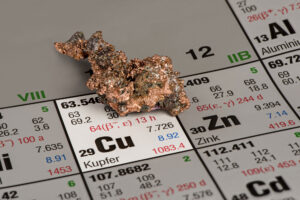

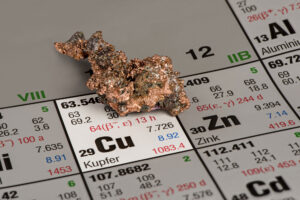

Copper (chem. symbol Cu) is one of the world’s most important industrial metals. More than 20 million tons of Copper are consumed annually. This high demand, which is driven in particular by the industrial growth in Asia (62% of world copper consumption is in Asia), results from its excellent features.

Copper (chem. symbol Cu) is one of the world’s most important industrial metals. More than 20 million tons of Copper are consumed annually. This high demand, which is driven in particular by the industrial growth in Asia (62% of world copper consumption is in Asia), results from its excellent features.

This versatile metal is mainly used as an excellent heat and electricity conductor. Although for example silver and gold conduct similar well, but are much more expensive. Aluminum conducts electricity better than copper does, however, it is problematic to handle and in contrast to copper is not so inert. This meant that copper is the undisputed standard material for electrical wires. It occurs in almost all power cables, transformers, switches, processors and similar products.

Also Renewables cannot perform without the excellent conductivity of copper. With increasing electrification of our transportation (car, train, plane) also applications for copper are increasing. Recent high-speed trains such as the German ICE 3, for example, require 2 to 4 tons of copper – more than twice the amount of a normal electric powered train.

In construction, copper is also a popular raw material: Almost 60 percent of all German homes have water pipes made of copper. In addition, it is used as roofing material and is popular due to its resistance to extreme weather conditions. Copper forms in the presence of air a green patina on the surface, each one of us knows those roofs in particular of older buildings.

Besides its application as copper coinage, the biocidal agent is currently most widely used. As such substance is used in antifouling paints for ships. This results in the prevention of the growth of micro-organisms (fungi, algae etc.), whereby ships can theoretically save up to 40 percent fuel. For the preventive wood preservatives, industry takes advantage of this biocidal effect as well.

At the same time, copper is also an essential trace element. Adult humans require daily about 1-1,5 milligrams of the material. We take it on by copper-containing foods, such as chocolate, liver, cereals, vegetables and nuts.

Nano Copper

Copper Nanoparticles are mainly used as a biocide and for electrical applications. In the information and communication technology small, precise switching and conducting paths are increasingly needed. This is supported, for example, by solutions or pastes made of copper nanoparticles, which can be selectively applied through novel printing process.

Copper Nanoparticles are mainly used as a biocide and for electrical applications. In the information and communication technology small, precise switching and conducting paths are increasingly needed. This is supported, for example, by solutions or pastes made of copper nanoparticles, which can be selectively applied through novel printing process.

Antifouling coatings for ship hulls are also considered as application for copper nanoparticles. But currently no product can be identified, which made the statement to use such particles as a biocide.

Unlike in the field of biocides for wood preservation: The wood is significantly improved by the use of copper nanoparticles in biocides, prolongs the life of wooden structures and thus significantly reduces the cost for the consumer. Aqueous formulations of copper nano – and microparticles in the order of 1 nm to 25 microns have been used for several years in the commercial wood preservation. The consumption of copper nanoparticles for this industry experts estimate that several thousand tons per year. Therby such wood preservatives have the potential to be one of the largest nano applications in Europe for hard woods such as Norway spruce (Picea abies) and silver fir (Abies alba).

Metallic nanocopper is self-igniting. The mixture of nanocopper with air (dust) is also ignitable without the influence of an ignition source. In contrast, nanoscale powder of copper oxide is not self- inflammable. Copper oxide dust just as little, so there is no possibility of a dust explosion in copper oxide ..

Occurrence and Production

In 2011, more than 16 million tons of copper from ore mines are mined. Already 5.3 million tons in Chile, currently the largest copper producer in the world. Copper is also good to recycle, so that even a large part of the global demand will be covered by so-called secondary copper.

Copper nanoparticles can be prepared by wet chemical methods or by flame synthesis. In the wet chemical variant copper salts, e.g. copper sulfate are reduced in the presence of a stabilizer (polymers, amine compounds, etc.) to nanoparticles. This one contains colloidal solutions of nanoparticles that can be processed directly. In flame synthesis under strongly reduced conditions cupreous compounds are burned, and so copper nanoparticles are obtained. There is the possibility of burning different metal-containing compounds, whereby hybrid metal particles (alloys) can be obtained.

How can I come in contact with this material?

How can I come in contact with this material? Copper (chem. symbol Cu) is one of the world’s most important industrial metals. More than 20 million tons of Copper are consumed annually. This high demand, which is driven in particular by the industrial growth in Asia (62% of world copper consumption is in Asia), results from its excellent features.

Copper (chem. symbol Cu) is one of the world’s most important industrial metals. More than 20 million tons of Copper are consumed annually. This high demand, which is driven in particular by the industrial growth in Asia (62% of world copper consumption is in Asia), results from its excellent features. Copper Nanoparticles are mainly used as a biocide and for electrical applications. In the information and communication technology small, precise switching and conducting paths are increasingly needed. This is supported, for example, by solutions or pastes made of copper nanoparticles, which can be selectively applied through novel printing process.

Copper Nanoparticles are mainly used as a biocide and for electrical applications. In the information and communication technology small, precise switching and conducting paths are increasingly needed. This is supported, for example, by solutions or pastes made of copper nanoparticles, which can be selectively applied through novel printing process.

The effect of Cu nanoparticles on soil-dwelling worms was tested by mixing the particles into the soil. Depending on the worm species, contradictory results have been achieved. Cu nanoparticles had an inhibitory effect on the propagation of worms but administered in the same amounts as copper salt it was more toxic than the particles in one study and less toxic or of equal toxicity in another study. The effect of Cu nanoparticles and copper salts led to very different gene activation response patterns, leading to the assumption that the copper nanoparticles cause a specific effect, which is not comparable to copper ions .

The effect of Cu nanoparticles on soil-dwelling worms was tested by mixing the particles into the soil. Depending on the worm species, contradictory results have been achieved. Cu nanoparticles had an inhibitory effect on the propagation of worms but administered in the same amounts as copper salt it was more toxic than the particles in one study and less toxic or of equal toxicity in another study. The effect of Cu nanoparticles and copper salts led to very different gene activation response patterns, leading to the assumption that the copper nanoparticles cause a specific effect, which is not comparable to copper ions . Studies on zebrafish draw the same conclusion additionally showing a damage to the gills. Cu2O nanoparticles were less toxic for zebrafish than copper salts. Carp showed a growth delay after

Studies on zebrafish draw the same conclusion additionally showing a damage to the gills. Cu2O nanoparticles were less toxic for zebrafish than copper salts. Carp showed a growth delay after  CuO nanoparticles disrupt the development of Xenopus embryos. The main intake route was the ingestion of particles. Consequently, damage to the gastrointestinal tract was observed, which was due to both the particulate form and the ions. An electron microscopic study showed an uptake of CuO particles (nano and micro) in the intestines of water fleas but for both particle types no uptake from the gut into the body was observed. Water fleas showed a higher sensitivity to nanoparticles compared with coarser particles or salts .

CuO nanoparticles disrupt the development of Xenopus embryos. The main intake route was the ingestion of particles. Consequently, damage to the gastrointestinal tract was observed, which was due to both the particulate form and the ions. An electron microscopic study showed an uptake of CuO particles (nano and micro) in the intestines of water fleas but for both particle types no uptake from the gut into the body was observed. Water fleas showed a higher sensitivity to nanoparticles compared with coarser particles or salts . A soil-dwelling water snail ingested more copper from nano copper oxide compared to coarser copper oxide and copper salts. Accordingly nano copper oxide had the greatest effects on growth, feed intake and reproduction of animals ..

A soil-dwelling water snail ingested more copper from nano copper oxide compared to coarser copper oxide and copper salts. Accordingly nano copper oxide had the greatest effects on growth, feed intake and reproduction of animals .. Copper oxide particles had a toxic effect on green algae. In order to prevent the leaching of copper ions, CuO particles were

Copper oxide particles had a toxic effect on green algae. In order to prevent the leaching of copper ions, CuO particles were