Layer-by-layer coated ceramic membranes for the resource-efficient production of drinking and process water

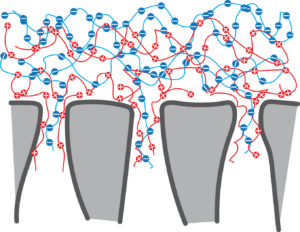

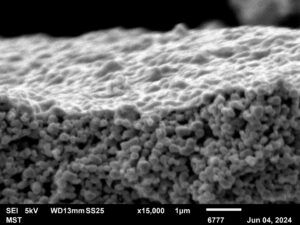

The “KeraRes” research project is developing an innovative membrane process for resource-efficient water treatment. The project focusses on developing a ceramic nanofiltration membrane (NF), which has a high efficiency in filtering and separating water impurities thanks to a so-called layer-by-layer (LbL) coating with polyelectrolytes. The system is particularly designed to safely treat water resources such as river water, waste water and rainwater in a single step. The developed membrane should be able to hold back particles such as microplastics and bacteria as well as dissolve materials as salts and organic substances and chemicals such as per- and polyfluoroalkyl substances (PFAS). At the same time, the membrane is designed to be regenerable, back-washable and, compared to conventional ceramic membranes, more durable and less vulnerable to fouling. Regenerability is ensured by removing the LbL-layer by pH adjustment. This way the membranes performance can be restored by reapplying the polyelectrolyte layer.

The project is divided into three phases: Membrane development, process development and upscaling. In the first phase the ceramic membrane will be developed and modified. Experimental optimization is used to determine the optimal parameters for the LbL coating process such as salinity, temperature and pH value. Following the successful development of these membrane modules, initial tests will be carried out on a laboratory and semi-industrial scale during the process development phase in order to test the durability of the coating and the backwashing behavior and to compare it with established polymeric NF systems. In addition, comprehensive analyses of the energy and material efficiency of the system are carried out in this phase to enable a well-founded evaluation as part of a life cycle assessment (LCA).

The final phase of the project is dedicated to upscaling. The task is to test the membrane technology for an application on a real scale and to adapt the process parameters for larger applications, for example in drinking water treatment or the provision of industrial water. In this phase, simulations and tests will be carried out with regard to throughput, residue management and technical requirements in order to optimize the membrane modules in terms of their performance and practicability. The project aims to advance development to the point where the KeraRes technology can be used in decentralized water treatment units, for example, making it particularly valuable for crisis relief.

Overall, the KeraRes project´s goal is to provide a scalable and energy-efficient solution for water treatment that meets the increasing demands for drinking and industrial water supply in various applications. With the possibility of regeneration and modularity, the system offers both ecological and economic advantages that make it attractive for the market in the long term.