Nanoscale Carbon Membranes for Fluid Separation to realise pollutant-free resource efficiency

The overall goal of the project is to demonstrate that nanoscale carbon membranes can be used for separation tasks with condensable components under chemically very demanding conditions for industrial applications. This is an integral part of the development of material innovations for a pollutant-free environment and increasing resource efficiency in industrial applications to reduce emissions.

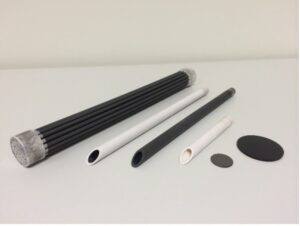

On laboratory scale, it is well known from literature that nanoscale carbon membranes have material-separating properties, especially for condensable components. Since many of these separation tasks in industrial practice are carried out under aggressive conditions (e.g. high temperatures, high pressure, presence of corrosive components or aggressive solvents), the components to be used must have appropriate chemical and thermal resistance. This is currently not the case or is only the case to a very limited extent with commercially available membranes. The exceptional chemical and thermal stability of various carbon modifications under such conditions suggests their suitability as a membrane, but also requires a stable support structure under these conditions. The overall goal is achieved through several sub-goals that cover the various aspects along the entire value chain. This includes the development of the carrier, the application of the separating membrane layer, the optimization of the process parameters for the membrane application and the assessment of industrial feasibility.