Aluminium is found in the form of aluminium ions as a natural component in drinking water and other foodstuffs, especially fruit and vegetables. Aluminium oxide particles agglomerate strongly, forming larger "particle clusters". In this form they are not very toxic to cells.

General Hazards

Aluminum-containing utensils for food storage or preparation such as kitchen utensils, cans or tins, foils or tubes from which the dissolved aluminum ions pass into the food may be additional sources of exposure. Moreover, aluminum compounds can be contained in gastric-acid neutralizers, so-called antacids, and in cosmetics and are used, for example, in roll-on deodorants due to their anti-perspirant effect. Compared to the uptake via food or antacids, the uptake of aluminum via utensils for food storage or preparation and cosmetics is rather low and amounts to clearly less than the uptake quantity that is assumed not to pose any health hazard according to an updated evaluation issued by the Joint FAO/WHO Expert Committee on Food Additives (JECFA, 2006).

Occupational-health studies of specific stresses and exposure in the aluminum powder industry have shown that finest aluminum powder can cause pulmonary fibrosis under unfavorable industrial-hygiene conditions. In Germany, the resulting disease which is referred to as aluminosis has been approved as such and workers have been recompensed for the related health problems since 1943 . The Senate Commission of the Deutsche Forschungsgemeinschaft has fixed the maximum admissible concentration (MAK-value) of aluminum oxides to amount to 1,5 mg/m3. Workers in the aluminum powder industry or welders in the automobile industry thus are required to wear suitable breathing protection.

So far, there is no scientific proof of a correlation between increased aluminum ion uptake from food including drinking water, pharmaceuticals, and cosmetics and the Alzheimer’s disease. Neither in dialysis patients nor in aluminum workers – both belonging to the groups of persons that are definitely exposed – were the Alzheimer-typical amyloid depositions in the brain observed in extremely many cases .

Studies on Living Organisms – in vivo

Within the project NanoCare, two different types of boehmite particles (primary particle sizes of 10 and 40nm) were scrutinized in in vivo studies. The experiments on rats that were made to inhale up to 28mg/m3 of the particles five days a week over a period of four weeks showed that inflammation of the lungs due to strongly agglomerated particles only occurred in the presence of the highest concentration. Moreover, enlarged macrophages and lymph node modifications were observed increasingly. Inflammations in the lungs occurred at inhaled particle doses of more than 1mg per lung. Similar results were obtained from instillation experiments carried out within the project. Instillation of more than 1,2mg of boehmite particles per lung in the respiratory tracts of the test animals caused damage to the lungs. In these studies, the NO(A)EL amounts to 0,6mg .

Studies Outside of Organisms – in vitro

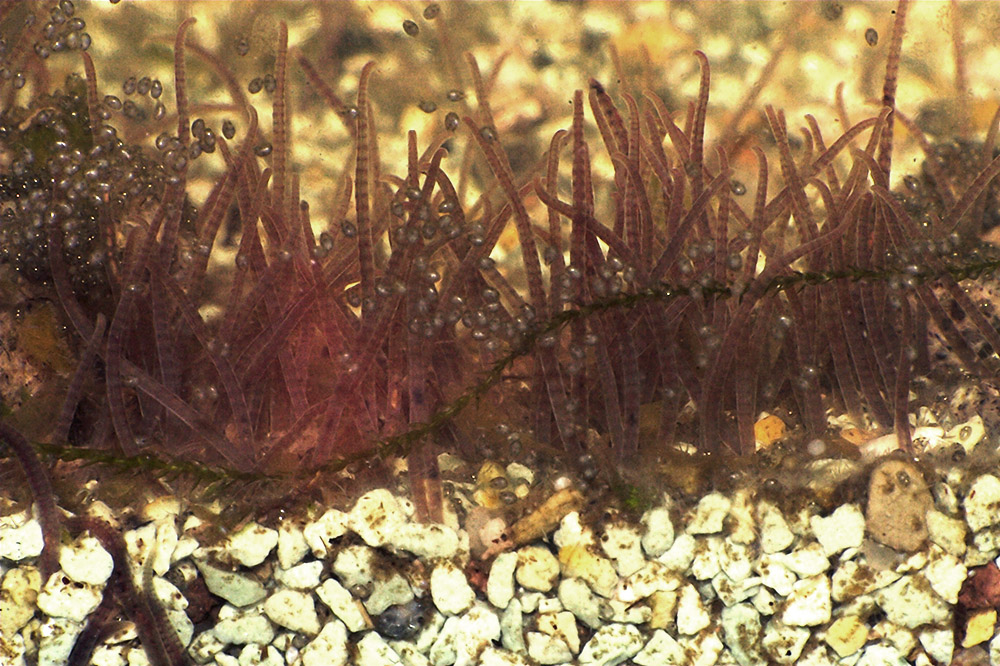

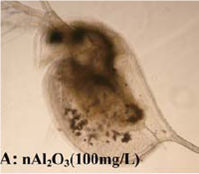

Studies of Al, Al2O3, and AlOOH (boehmite) particles have shown that these particles tend to strongly clog and form agglomerates. These agglomerates can be taken up by the cells but are always found in vesicles, which means that they do not occur freely in the cells and are practically never detected in the cell nucleus. Studies of human lung cells have shown Al2O3 to have only small harmful effects on the cell division and cell vitality and have proved that even very high doses do not cause formation of harmful reactive oxygen species (ROS).

Aluminum oxide (Al2O3) which, for example, is used in orthopedic ceramics, has also been investigated for its genotoxicity. Very high doses were observed to have only minor mutagenic effects. Aluminum oxide fibers were found to be more genotoxic than nano- or micro-scale particles. Aluminium particles are more toxic than aluminum oxide particles. Only very high doses of Al2O3 can decrease the function of the mitochondria (only at or above 200µg/ml, the function of the mitochondria is reduced by 15%) and can cause (programmed) cell death of part of the cells.

Boehmite, an aluminum oxihydroxide (AlOOH), was studied within the NanoCare project. For the human lung cell line A549, a threshold concentration of at least 50µg particles per cm2 was determined. When the cells were treated with at least that concentration (LOEL) for more than 72hours, they were observed to become stressed while inflammation markers were produced. No effects were triggered by low doses of AlOOH in any of the different cell lines of different origins. Experiments on the mobility of nanoparticles across cell barriers (such as the air-blood barrier in the lung) showed that boehmite does not pass through cells. The barrier function of the cells is not influenced by the particles.

Using the so-called vector model which displays some of the elementary cell effects, partners of the NanoCare project proved that AIOOH particles are among the low-toxicity materials. Excessive, overloading concentrations of 60-120µg particles per 106 macrophages were observed to damage the cells but did not lead to the formation of harmful reactive oxygen species (ROS). Damage due to realistic doses of Al particles is not expected .