Providing access to sustainable feedstocks by combined chemical and biotechnological process development

The chemical industry is one of the biggest drivers of economic and scientific developments in Germany and is responsible for the production of various essential base materials for sustainability technologies such as wind- and solar energy. Commonly employed chemical processes still rely on fossil raw materials with high carbon footprint, e.g. natural gas or crude oil. Sustainable alternatives are sparsely available with limited quantities of suitable material. Generating broad access to sustainable raw materials offers the possibility of the sustainable production of base and specialty chemicals. This would enable chemical industry to take the next step towards a carbon neutral value chain.

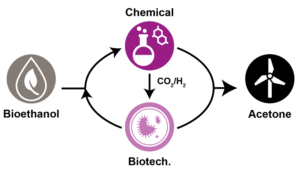

Aim of the project BETA (Bioethanol to Acetone) is the development of an efficient process for the sustainable production of the base chemical acetone from bioethanol. Stemming from the advancing electrification of the transportation sector, a reduction in demand for conventional biofuels is expected over the coming years. This will lead to an increase in bioethanol availability. Additionally, significant advancements in the production of bioethanol from waste are expected. Consequently, bioethanol is a promising feedstock for the carbon neutral manufacturing of chemicals.

Acetone is an important component of modern crosslinkers for polymers and composites, which are used for the manufacturing of wind turbines among other applications. As part of the project BETA, new

(bio-)catalysts for the conversion of bioethanol to acetone will be developed providing expedient access to the sustainable feedstock combined with a reduction of formed byproducts and waste. The incorporation of modern membrane technologies is envisioned to allow for a highly energy efficient execution of the process on industrial scale. Additionally, extensive process simulations and sustainability analyses will be conducted to evaluate the potential of the developed chemical process. Primary focus is the complete valorisation of the input resources and reduction of the carbon footprint of formed products.

Overall, the project provides a solid foundation for industrial implementation and extension to other important feedstocks for chemical industry, thus significantly contributing to the goal of reaching climate neutrality in the German manufacturing industry.